We make decking easy with

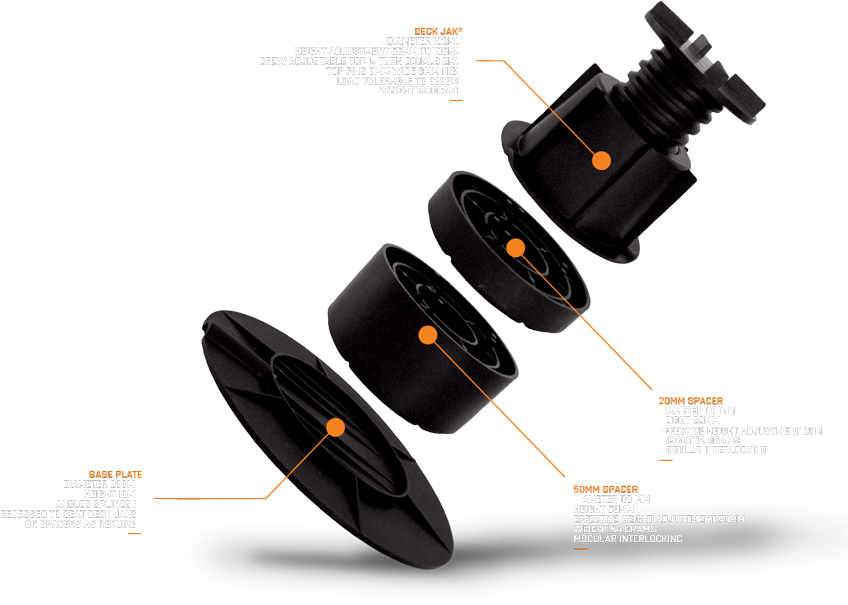

Deck Jak®

Durable, practical systems that make

decking, roofing & foundations easier

The Deck Jak® System is a rigid height adjustable proprietary support system for concrete pavers, structural

tiles or timber panels or other approved trafficable surfaces.

tiles or timber panels or other approved trafficable surfaces.

The Joist Jak™ Flooring Systemis a rigid, height adjustable self leveling proprietary support system for joist type constructed surfaces.

Reo Pegs are designed to act as proprietary supports for two or four vertical bar cage reinforcing, or trenchmesh. They provide a quick, easy and cost-effective means of support during the concrete pour, and can double as height pegs.

3 Simple reasons why you should shop with us:

Designed specifically to reduce installation time and expense

Made from long lasting

robust materials

robust materials

More cost effective and

simpler than similar systems

simpler than similar systems

All our building systems are designed specifically to cope with tough conditions and to be easy to install.

We’ve also made them to be as cost effective as possible, providing a better product at a lower price

Proudly Supported By

If all trades people and suppliers were as professional as steve, renovations would be a dream

GREG, AUCKLAND

Contact

Urban Building Products Ltd

60 Kerwyn Ave

East Tamaki

Manukau 2013

Phone: 09 277 7538

Fax: 09 277 7539